Turck’s hazardous area quick disconnect wiring system and the BL20 remote I/O system support the modular concept of Enerflex’s production facilities for oil and gas.

The Calgary based oil and gas specialist Enerflex initially builds its modular production facilities to test the systems and pre-commission the facility, before it will be broken down into container sized loads for shipping. In order to realize the benefits of this modular concept, the Enerflex engineers rely on Turck’s hazardous area quick disconnect wiring system and the BL20 remote I/O system.

The Canadian oil and gas company Enerflex, based in Calgary, Alberta, has divisions for both services and products. While the service side lists instrumentation and controls, as well as mechanical services for compression in its offerings, the products side includes oil and gas production processing, compression and environmental services. Enerflex Production and Processing (P&P) is responsible for the design and construction of complete, ready to commission modular production facilities for the oil, natural gas and chemical industries.

Enerflex has been able to design the mechanics of a plant to break down into container sized parts for years using flanges and brackets, but the instrumentation has always been a trade-off.

Improving the physical layer

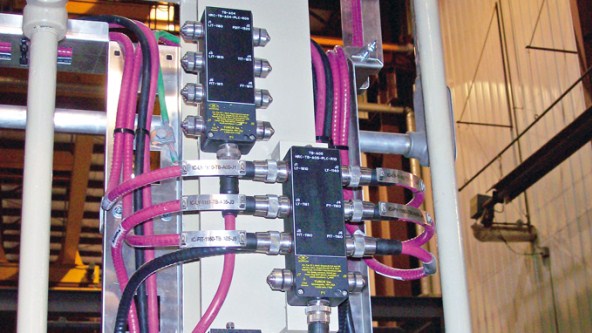

This is where Turck has been able to help. The Turck quick connector system is innovative in that it allows for the use of a rugged connector system to terminate to process instruments in the field and consolidate those signals at a pre-made junction box. From the junction box, a multi-conductor home run cable is installed across skid joints back to a control cabinet.

The first project started in 2008, when an American oil and gas company wanted Enerflex P&P to build a complete amine gas sweetening facility for processing natural gas.

Quick disconnect and remote I/O

Enerflex decided to use the Turck hazardous area quick disconnect wiring system and the BL20 remote I/O system. BL20 is a cost effective and easy to configure system for process remote I/O solutions in hazardous locations. They chose BL20 I/O running the EtherNet/IP protocol, which has a worldwide Division 2/Zone 2 approval.

The design needed to accommodate a large number of signals and still reduce the wiring footprint while maintaining the 20 percent customer specified spare capacity.

Once the wiring, PLC programming and plant commissioning was completed at the Enerflex factory, the entire skid was broken down into smaller sections for shipping. This meant that the home run cables from the junction blocks were disconnected and rolled back to the skid break point and capped off for transport. Once onsite and reassembled by local workers, the process of testing all the signals was very short because of the keyed nature of the connectors. These keyed connectors meant that the job was done with no mistakes, further increasing efficiency and reducing onsite expenses.