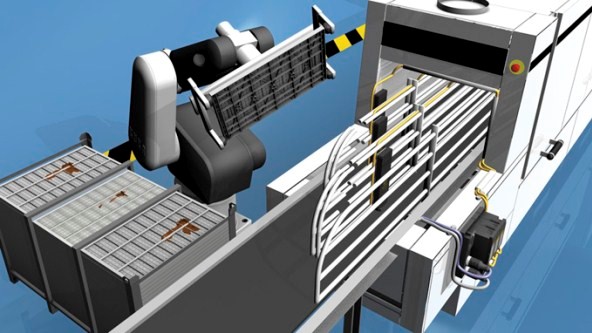

BL ident reliably detects each and every chocolate mould and thus improves the efficiency of systems and quality of products.

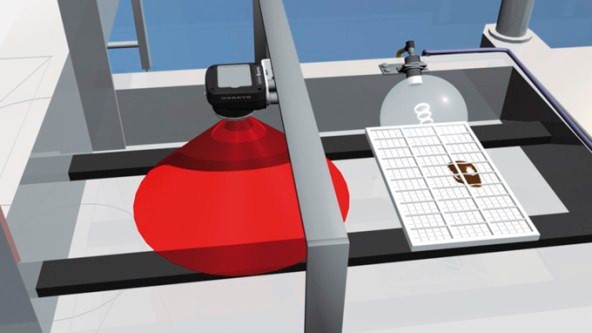

With the help of the RFID-technology chocolate moulds are able to control their individual chocolate production process. They tell the depositing machine how they are to be filled and the washing machine how they are to be cleaned. This enhances the efficiency of the production plant. The product quality is also improved, because falsely filled moulds are removed precisely and reliably. Moulds with repeated problems are eliminated from production.

YOUR BENEFITS

- BL ident reliably detects each and every chocolate mould and thus improves the efficiency of systems and quality of products

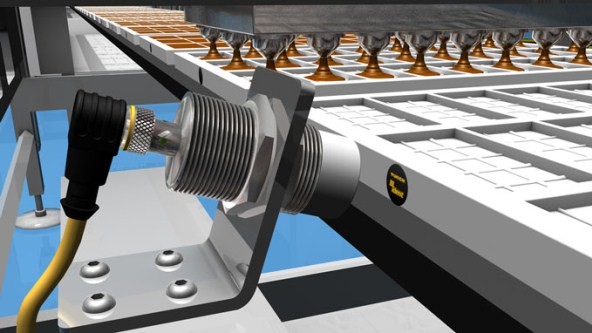

- Application-optimized data carriers and read/write heads for food and beverage application