In the modular expandable automated production equipment from Gefasoft, Turck’s BL ident RFID system

ensures transparent production processes.

As a specialist for manufacturing automation, image processing, and identification, Gefasoft has made a name for itself among the major manufacturers in the automotive and semiconductor industry. In its use of RFID, the Regensburg-based company also has many years of experience with systems from different manufacturers, and they now prefer to use BL ident® from Turck for their assembly and automated measuring equipment.

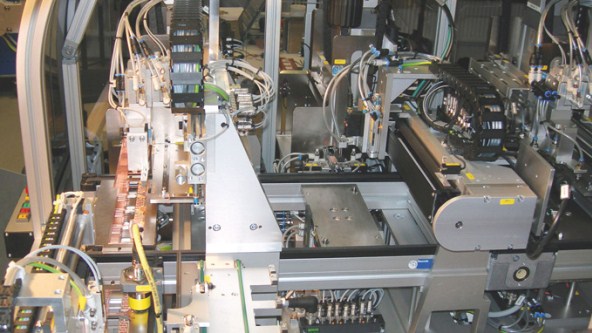

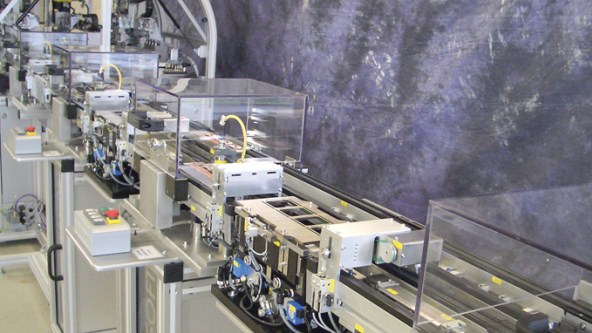

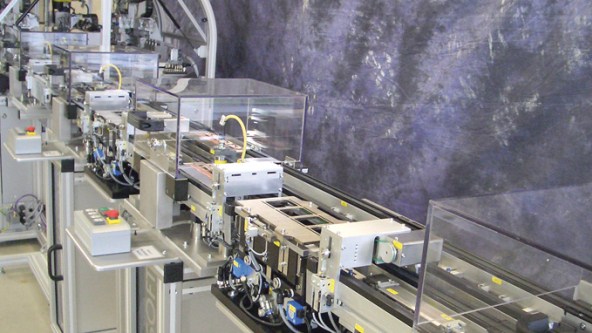

Modular assembly system

For a well-known customer from the semiconductor industry, the specialists from Regensburg have developed an automated loading and unloading system for the manufacturing of multi-chip modules. This system links numerous wire bonders and simultaneously handles quality control of the bonded chip modules. The machine has a modular design and consists of one loading and unloading module with three magazine handling stations, transfer paths on the wire bonder, as well as the transverse and reverse transport routes for the parts carrier. Before handlers transfer the processed chip modules to the good parts magazine, they are checked for correct wiring using RFID and image processing. A reject parts punch marks the defective parts with a hole on a determined position.

The parts carrier and the corresponding stations are equipped with the BL ident RFID system from Turck, which is connected to the plant’s control system via Profibus DP. Overall, six read and write points are currently integrated in the system: one on the ramp of the loading area, one on each in the maintenance positions in front of the three wire bonders, one with the transverse transport and one in front of the reject part punch. “In the system expansion phase that is now complete, we could also have handled the identification of the parts carrier with alternative technologies,” explains CEO Grünbauer, “but precisely because of the modularity and expansion capability of the system, we decided in favor of the RFID technology. It means that the system can be easily upgraded.”

Data carriers in metal

Before making the decision to go with the BL ident system, project engineer Markus Müller tested numerous solutions from several suppliers. “I was very excited at how stably the Turck system operated,” explains Müller. “The other systems had continual difficulties both with regard to connecting to the controller, as well as with the stability.” One reason for the problems could have been the unusual positioning of the data carrier directly in the metal of the parts carrier. For stability reasons, it could only be made of steel with a hardened surface. “We have a metal contact between the parts carrier and the data carrier. This should not actually be the case, but due to general construction conditions, the data carrier could not be mounted on its own nor positioned otherwise. And our tests showed that the Turck system had no problem with this issue, it functioned on the first go,” explains Müller happily. Turck now offers special data carriers for installation on or in metal. The system has now been working for almost one year in double and triple shift operation and there have not yet been any outages.

Documentation of the process steps.

Gefasoft uses the RFID technology in order to document all process steps directly on the parts carrier. The first read-write location is located on the outlet of the loading machine. Here, the data carrier receives information as to whether all designated components were successfully mounted and can be further processed. If the four points in the parts carrier are properly filled, the content of the data carrier is added so it includes the processing release. Information concerning the successful or unsuccessful processing of each component is added on the following processing stations. Finally, on the last RFID station, the data is exported and the individual parts are forwarded by the operator either to the good parts magazine or the reject parts punch, depending on their classification on the data carrier. The production data is archived per batch in a report file.

Summary

For its automated production systems, Gefasoft searched for a stable RFID system that has a modular and expandable design and is easy to connect to the control system. With BL ident from Turck, the Regensburg specialists found a system that meets all the requirements. BL ident was even able to master the challenge of mounting the data carrier. For Harald Grünbauer, reason enough to continue building on BL ident. “With what we have experienced, we will also use the RFID solution from Turck in our systems in the future,” promises the CEO.